FAQs

Power Temp Systems, Inc

Portable Power Distribution FAQs

The GFCI, however does not protect from line-to-line contact hazards (such as a worker holding two “hot” wires or a hot and a neutral wire in each hand). It does protect against the most common form of electrical shock hazard – the ground fault, and it also protects against fires, overheating, and destruction of insulation on wiring.

- Using the existing service disconnect in conjunction with a trapped key interlock.

- Double throw manual transfer switch.

- Automatic manual transfer switch.

Related Products

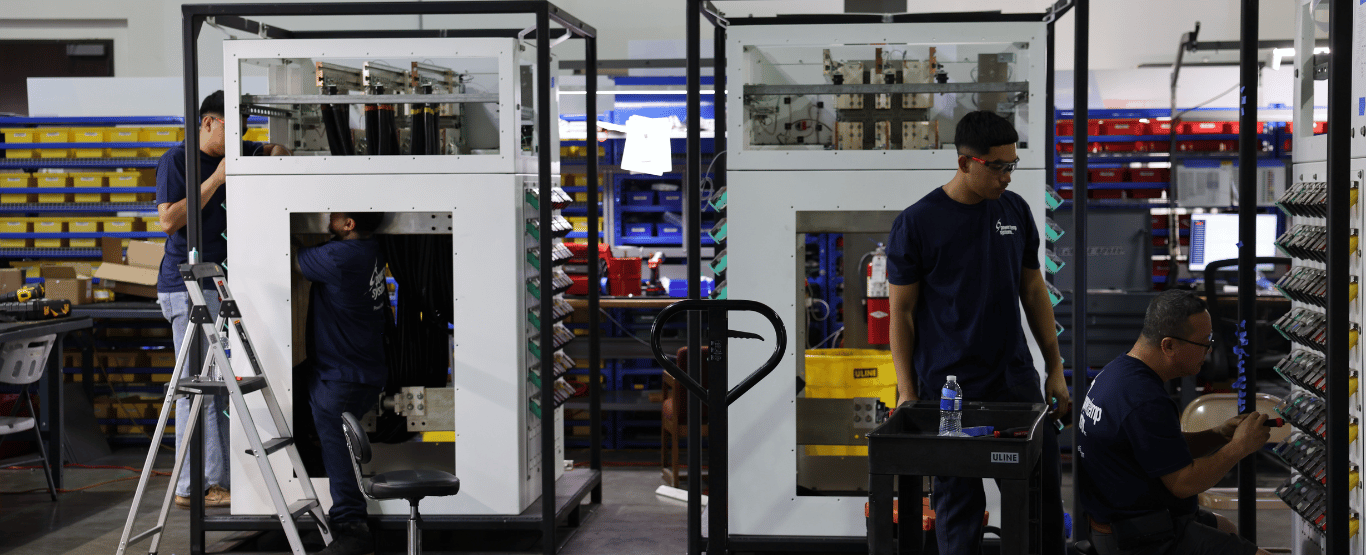

Portable Power Distribution Carts, also known as our Original Series of power distribution boxes,...

If you need multiple 125V or 250V GFCI Protected outlets to provide temporary power for a constru...

Our 2000A to 12000A Common Bus Panels are a complementary product to all generator rental fleets ...

NEC 70, NFPA 70B, OSHA 70E, Compliance Ensuring Compliance and Safety in Electrical Systems Meeti...

Reliable Power Transition Solutions

Success Stories

Gunthrett Power cannot speak highly enough about Power Temp Systems, with whom we have had the privilege of partnering for the last 4 years. Throughout that time, Power Temp has consistently demonstrated exceptional qualities that make them stand out in the industry.

GUNTHRETT POWER – Kristi Gunther, Inside Sales Manager

PowerTemp Systems delivers highly customizable and innovative solutions that help our customers solve rapidly evolving emergency power needs. The PTS team is incredibly quick to respond, ensuring seamless support and reliability every step of the way. Exceptional service!

SWMCO – Brad Jenkins, President

First and foremost, their problem-solving abilities are remarkable. Time and again, they have shown an impressive aptitude for tackling complex challenges and finding innovative, effective solutions. Whether it’s addressing unforeseen production issues or resolving technical hurdles, their team approaches each problem with a clear, methodical mindset, ensuring that no issue is left unresolved.

GUNTHRETT POWER – Kristi Gunther, Inside Sales Manager

As a brand-new rep of PTS, I was very impressed with the training and the company culture you all seem to have.

Cal Industrial Sales, Inc. – Jaideep Dhillon

The teamwork displayed by Power Temp Systems is truly outstanding. Every member of the team contributes their expertise and works with others to deliver outstanding product. This cohesiveness is integral to their ability to put out fires and ensure that tight deadlines or unexpected disruptions do not derail their progress.

GUNTHRETT POWER – Kristi Gunther, Inside Sales Manager

What I like most about the Power Temp team is their responsiveness and communication level. From the initial quote request to submittal review and placing an order, the process is streamlined, well executed, and convenient. I can’t think of a time where if there were any questions, I could not get in touch with someone to discuss the problem. I appreciate that their representatives take the time to call with questions. In my opinion, a call is better received than an email…

Their pricing is about in line, perhaps a touch higher than others, but it is well worth it for the ease of doing business. The sales team is also willing to negotiate pricing to “win the job” and maintain a strong partnership. I also really like that their specialists can customize any product to provide a solution. Power Temp has become our preferred partner, especially for customized solutions. We look forward to growing our partnership together.

About Power Temp Reps – from Caleb Schaubroeck, Lead Sales Engineer, Total Energy Systems, LLC

In terms of professionalism, Power Temp excels. They maintain a high standard of conduct, always acting with integrity and respect in every interaction. Their communication is timely, transparent, and effective.

GUNTHRETT POWER – Kristi Gunther, Inside Sales Manager

I have appreciated the quick response to my requests for quotes from the Power Temp team and their willingness to supply engineered Docking Station solutions.

About Power Temp Reps – from Jim Green, Generator Systems LLC

Their technical expertise is unparalleled, and their creativity sets them apart from other manufacturers. Not only do they apply established best practices, but they also go above and beyond by thinking outside the box and bringing fresh, creative solutions to the table. This blend of technical know-how and innovation has been invaluable in optimizing production and delivering exceptional results.

GUNTHRETT POWER – Kristi Gunther, Inside Sales Manager

I would like to extend my sincere thanks for the excellent engineering solutions Power Temp provides and for their continued availability to support us throughout the process.

Their expertise and responsiveness have been invaluable in ensuring that our projects progress smoothly. The solutions they deliver are not only effective but also innovative, addressing both the technical and practical aspects of job requirements. Their willingness to be available whenever needed has made a significant difference, allowing us to move forward confidently and without delay.

We truly appreciate their dedication, professionalism, and the exceptional service they provide. We look forward to working together on future projects and continuing this strong partnership.

Once again, thank you to Power Temp for your hard work and ongoing support.

About Power Temp Reps – from John Schreiber, Inside Sales Power Generation, Cummins Sales and Service

Power Temp Systems is a reliable, skilled, and an indispensable part of our operations. Anyone seeking a top-tier power distribution partner should look no further.

GUNTHRETT POWER – Kristi Gunther, Inside Sales Manager

Stay Updated with Our Latest News and Innovations

Looking for more insights?

Check out our News & Resources for more Educational Content, Product Information, and more.